TECNICAL CHARACTERISTICS

Autwomatic: Production of Type II Water (Analytical Grade) according to ASTM D1193 and ISO 3696 standards

Specially designed to automatically feed to Clinical Analyzers.

|

Versions |

Liter/hour |

Purification Module |

UV Lamp |

Final Filter 0.22 micron |

By Pass Security |

|

AUTWOMATIC CLINICAL 20 |

20 |

X |

X |

X |

X |

|

AUTWOMATIC CLINICAL 40 |

40 |

X |

X |

X |

X |

|

AUTWOMATIC CLINIAL 60 |

60 |

X |

X |

X |

X |

|

AUTWOMATIC CLINICAL90 |

90 |

X |

X |

X |

X |

|

AUTWOMATIC CLINICAL 120 |

120 |

X |

X |

X |

X |

Based on a sequential purification (sediments filtration, dechlorination, reverse osmosis, deionization). It has an option for photo-oxidation system and final filtration of 0,22 μm.

Specially designed to automatically feed to clinical analyzers.

Reduces the number of stops for maintenance and change of consumables.

Freshly produced Water Type II, with no accumulation in a final tank

The water supplied to Autoanalyzer is newly produced. Differently from other equipment, there is no storage of the final water, in order to avoid its deterioration. The osmotic water is stored in pressure tanks of 50, 100 and 250 liters.

Storage Tanks

Atmospheric Systems When the customer requires, our systems can work with atmospheric deposits 50,100,200 and 500 liters

Monitoring

Continuous monitoring of the purification process parameters:

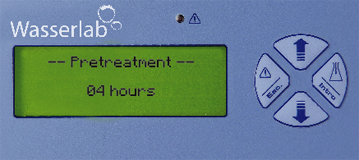

- Real number of working hours of the equipment.

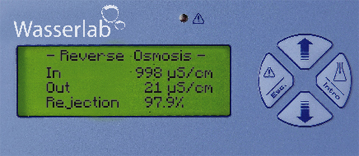

- Feed water conductivity (± 1 mS/cm).

- Osmotic Water conductivity (± 1 mS/cm)

- % performance of the reverse osmosis module (± 0,1%).

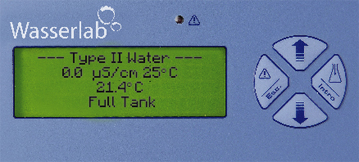

- Conductivity of the produced Type II Water (± 0,1 mS/cm).

- Water temperature. All conductivity measurements are compensated at 25ºC.

- Status of the equipment (producing/full tank/dispensing).

Automatic operation

The equipment starts and stops automatically, thus guarantying the production of Type II Water. Automatic stop in case of water supply cut.

Parameters customizing

The user can fix different parameter values, according to the control requirements:

- Pre-treatment time.

- Minimum performance of the reverse osmosis module.

- Maximum conductivity of the produced Type II water.

Warnings

The equipment warns, by a visual and audio message, of the need to replace the consumables, according to the fixed values:

- Pre-treatment change

- Interchange resin change

- Change of the reverse osmosis module

- Warning of malfunction of conductivity and temperature probes

Ultraviolet Lamp and Final Filter

The disinfection equipment emits ultraviolet radiation in two wave lengths, leading to a reduction of the bacterial content of 5 logaritmic cycles. This provides the user with water with minimum bacterial contamination if needed and produces the oxidation of organic material traces in the water.

For those laboratory applications where the bacterial contamination is critical, a final filter of 0.22 microns ensures a bacterial count ≤ 1 ufc/ml.

Conductivity meter calibration and system verification

Autwomatic software allows the adjustment and calibration of the conductivity meter by a traceable certified standard, according to the national standards of the German Deutscher Kalibrierdienst (DKD).

Security system via By-pass

When Autwomatic is supplying Autoanalyzers, Wasserlab has designed an auxiliar system able to produce Type II Water directly from tap water, without generation of burbles, reducing the stops of autoanalizers.

Security system by double sensor monitorization

The equipment includes two conductivity sensors of Type II Water. This allows to detect that first deionization module is exhausted. On this way it allows to plan maintenance operations on time and assuring the continuous work of Autoanalyzer.