Advantages of the Wasserlab systems of Type II water

One of the unique technical aspects of the Wasserlab water purification systems is the use of pressurized tanks for the storage of purified water.

One of the bases of the water purification systems from any manufacturer is the use of reverse osmosis membranes. The production rate of the reverse osmosis membranes is low. Since the purified water demanded from the user requires to be quickly and in a certain amount, the storage of purified water becomes essential.

The production flow rates of benchtop laboratory equipment usually range between 3 and 10 liters per hour. This flow rate is quite low if an immediate demand of a certain volume of water is needed for laboratory use.

Typically, manufacturers of water purification systems store the final purified (Type II) water in plastic atmospheric tanks, from which purified water is dispensed. To maintain the quality of the stored purified water, continuous recirculation of the water and ultraviolet systems are required to minimize bacterial contamination. Additionally, a vent filter is needed to capture the CO2 dissolved from the air. CO2 in contact with water reacts and increases the purified water conductivity deteriorating the water quality.

To obtain a better Type II water quality, Wasserlab´s purification systems work in a different way. Wasserlab makes use of pressurized tanks that store the osmotized water produced from the osmosis bottleneck stage previously described. In the moment the user demands Type II water, the stored osmotized water passes quickly through the last purification stage (Deionization module) producing fresh Type II water at the considerable dispensation flow rate of 60-70 liters per hour.

The numerous advantages of this system design, as well as the operation and characteristics of the storage tank are described below:

Features and Advantages of Osmotized Water Pressure Tank

How does it work? Features

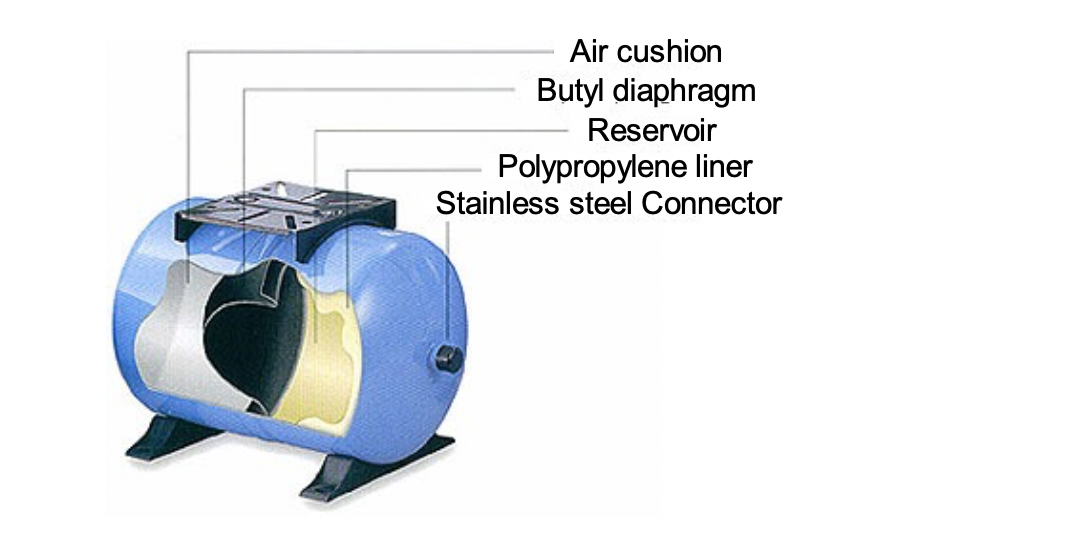

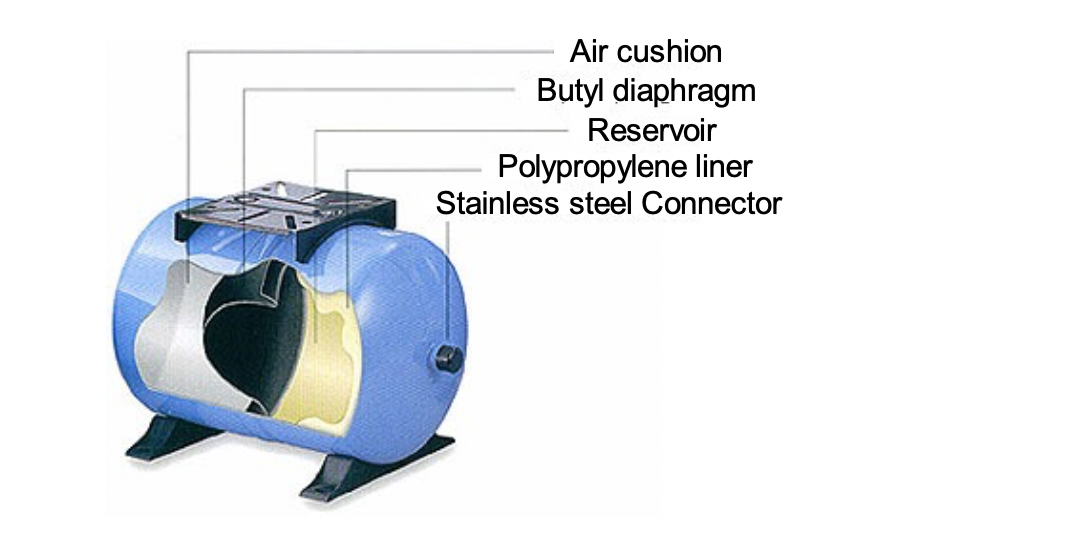

Features • Water storage chamber consisting of a butyl diaphragm and a polypropylene liner. It prevents bacterial growth and water contamination.

• Metal cover (more resistant than plastic)

• No pressure loss

• Stainless steel connection

• Approved by NSF ANSI 58 and 61

• Approved by IAMPO International Association of Plumbing and Mechanical Officials

• Approved by FDA : incorporates 100% chlorine-resistant butyl membrane

• CE Marking

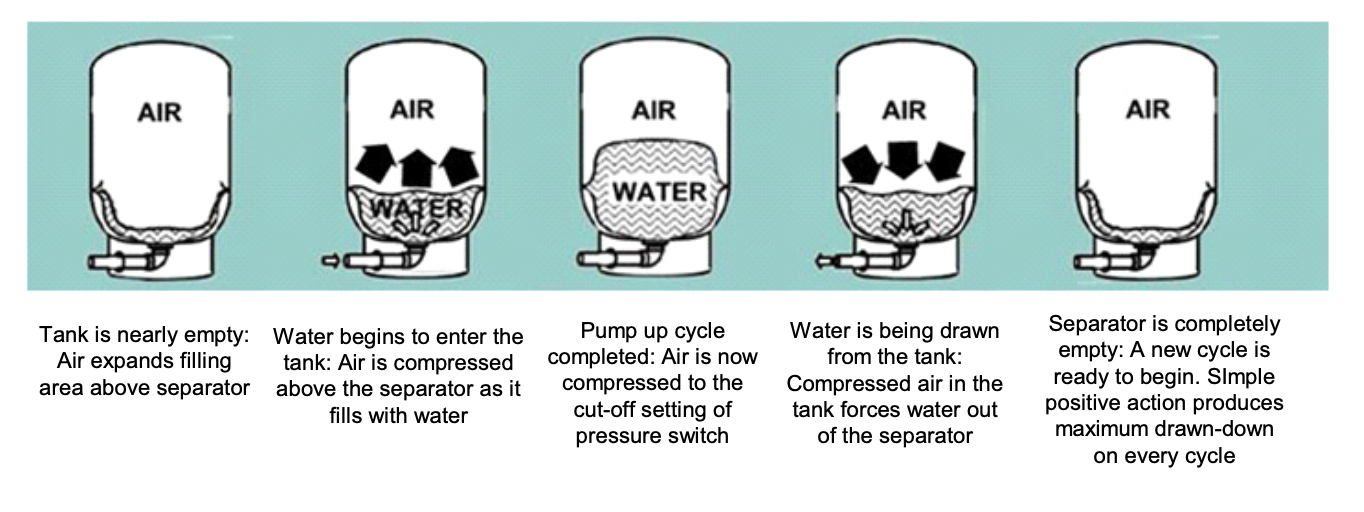

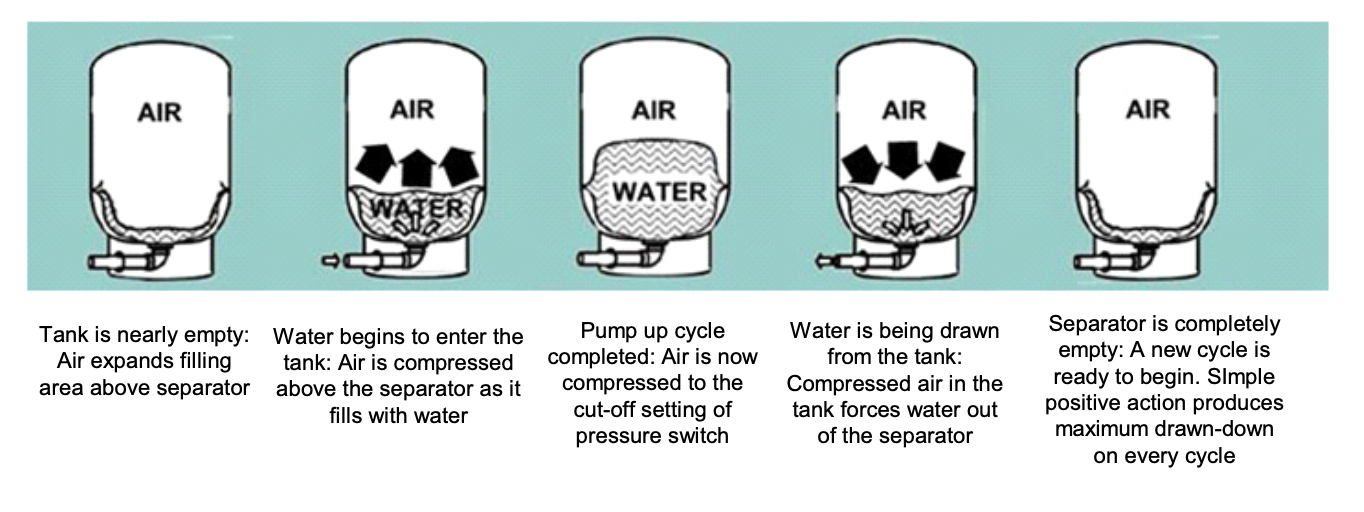

Wasserlab pressurized tank operation diagram

Advantages of the System

Advantages of the System• The water stored in the tank is not in contact with light or air, it remains completely stable both at the ionic level (the stored water is not ionically degraded by CO2 dissolution) and microbiologically (the stored water is pressurized at 3-4 bar, which inhibits bacterial growth). Consequently, our systems produce water of better quality in comparison to the water produced from systems that store the final Type II Water.

• It removes the need to install an ultraviolet system in the tank and a vent filter for CO2 retention. Since fewer references of consumables are needed, the operating cost of the equipment is optimized.

• It removes the need for water recirculation in the tank. Consequently, no additional pressure pump is needed.

• Any Type II Water system from Wasserlab also allows the dispensation of osmotized water from the tank. This option is useful for numerous laboratory applications such as material cleaning, automatic feeding of dishwashers or autoclaves, etc. The possibility of dispensing both osmotized and Type II water from a single equipment allows the customer to optimize the operating cost according to the type of water used.

• Tanks available in 10, 30 and 50 liters, depending on Wasserlab models.

• Wasserlab offers the possibility of connecting several tanks in series in order to increase storage capacity.

• The tanks need to be installed at a maximum distance of 10 meters from the water purification equipment. Therefore, the laboratory space is optimized.